Over the years, Haobang has designed hundreds of different plastic parts. Whether you require a basic or complex mold, we have the skills and experience to design your mold accurately and on time.

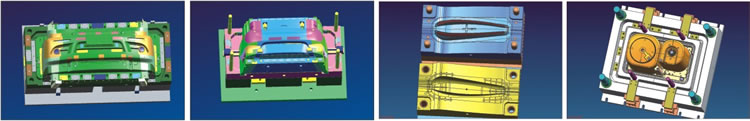

We offer extensive 3D mold design services ranging from simple parting line splits to fully 3D mold assemblies with UG software. Our 3D mold design models include parting lines, rounds, fillets, and drafts.

We send 3D Mold Designs and individual component models of cores, cavities, slides, and EDM electrodes to mold makers for CNC programming. By creating mold components as 3D models, the CNC cutter path can be programmed directly from the resulting geometry by UG.

Our engineers will work with you to develop the mold you need using three-dimensional modeling and state-of-the-art technology to ensure a precise result.

The following is a partial list of current mold steels and components used by Haobang’s Design Division. At the same time, we can design mold according to customers’ requirement.

Mould steel: 718,718H,S136,S136H,420ESR from ASSAB of Sweden.

P20,P20+S,P20+Ni,420,H13,01 from LKM.

NAK80 from DAIDO of Japan.

Most mold bases and standard components come from LKM, DME and HASCO.